Headline: Konix: Where Innovation Meets Precision – Powering Global Industries from Our Core

In an era demanding resilient supply chains and uncompromising quality, the Konix factory stands as a beacon of advanced manufacturing capability. More than just a production facility, Konix is a meticulously engineered ecosystem where cutting-edge technology, stringent processes, and a deeply skilled workforce converge to deliver exceptional components and solutions for global industries. Located strategically in Shenzhen, Konix has rapidly evolved into a trusted partner for clients demanding precision, reliability, and innovation.

The Technology Edge: Automation & Precision

Understanding that precision and speed are non-negotiable, Konix leverages automation strategically. Collaborative robots (cobots) work seamlessly alongside our skilled technicians on repetitive or high-precision tasks, enhancing both safety and throughput. Automated inspection systems provide 100% critical dimension verification for high-volume runs. Our investment in cutting-edge tooling and adaptive machining techniques allows us to tackle highly complex, low-volume prototypes and high-volume production runs with equal agility and precision, setting new industry benchmarks.

Engineered for Excellence: Core Capabilities

At the heart of Konix lies a commitment to mastering complex manufacturing challenges. Our core capabilities are built upon:

-

Advanced Machining & Fabrication: Housing state-of-the-art CNC machining centers (multi-axis), precision grinding equipment, automated welding systems, and sophisticated stamping presses, Konix handles intricate geometries and diverse materials – from high-strength alloys to specialized polymers – with micron-level accuracy.

-

Integrated Assembly & Testing: Moving beyond component production, Konix features dedicated, streamlined assembly lines equipped with automated guided vehicles (AGVs) and robotic assistance. Rigorous in-process and final testing protocols, including coordinate measuring machines (CMM), functional testing rigs, and non-destructive testing (NDT), ensure every unit meets or exceeds specifications before leaving our doors.

-

Smart Manufacturing Foundation: Konix embraces Industry 4.0 principles. Real-time production monitoring systems, integrated ERP/MES software, and data analytics drive continuous optimization, predictive maintenance, and unparalleled traceability throughout the entire value chain. This digital backbone enhances efficiency, minimizes downtime, and guarantees consistent quality.

Quality & Sustainability: Embedded in Our DNA

Quality at Konix isn’t just a department; it’s an intrinsic part of every process and ingrained in every employee. Our factory operates under a certified [Mention specific certifications, e.g., ISO 9001:2015, IATF 16949, AS9100D, ISO 14001] quality management system. This commitment extends to our environmental stewardship. Konix actively implements sustainable practices, including [Mention specific initiatives, e.g., significant waste reduction programs, energy-efficient machinery, water recycling, renewable energy sourcing, responsible material sourcing], minimizing our ecological footprint while maximizing operational responsibility.

Empowering People, Serving Communities

The Konix factory thrives because of its people. We invest heavily in continuous training and skills development, fostering a culture of problem-solving, ownership, and innovation. Our skilled engineers, machinists, technicians, and support staff are the true engine of our success. Konix is also proud to be an integral part of the Shenzhen community, providing stable, high-quality employment and actively engaging in local initiatives. We believe our success is intrinsically linked to the well-being of our workforce and our surroundings.

Partnering for the Future

Konix isn’t just a supplier; we are a solutions partner. Our engineering teams work collaboratively with clients from the design phase (DFM – Design for Manufacturability) through to volume production and beyond. This proactive approach ensures manufacturability, optimizes costs, accelerates time-to-market, and delivers components that perfectly integrate into our clients’ final products. Whether serving the demanding needs of [Mention Key Sectors, e.g., Aerospace, Automotive, Medical Devices, Industrial Automation, Energy], Konix provides the reliability and technological edge critical for success.

Looking Ahead: The Konix Vision

The Konix factory is a dynamic entity, constantly evolving. We are committed to ongoing investment in the latest manufacturing technologies, expanding our capabilities in areas like [Mention future focus areas, e.g., additive manufacturing (3D printing) for tooling/parts, further automation integration, advanced material science applications], and deepening our sustainability commitments. Our goal remains steadfast: to be the undisputed partner of choice for world-class precision manufacturing.

“At Konix, we see manufacturing as an art form driven by science,” says [Name, Title, e.g., Jane Doe, CEO of Konix Manufacturing]. “Our factory is the physical manifestation of our dedication to pushing boundaries, ensuring quality in every detail, and building lasting partnerships that power progress for our clients worldwide. We don’t just make parts; we engineer solutions and enable innovation.”

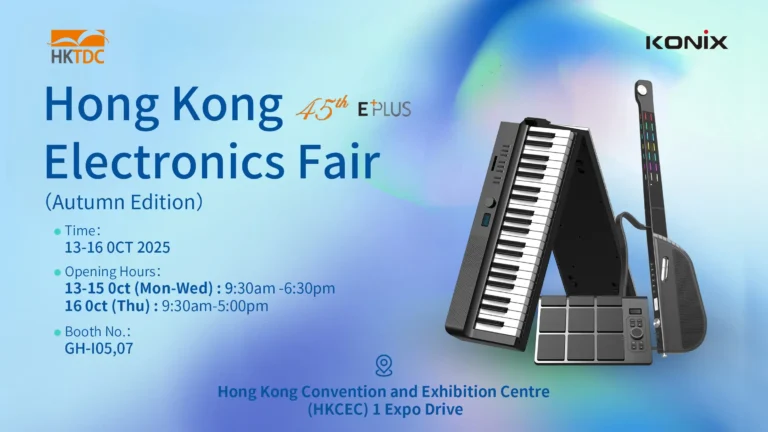

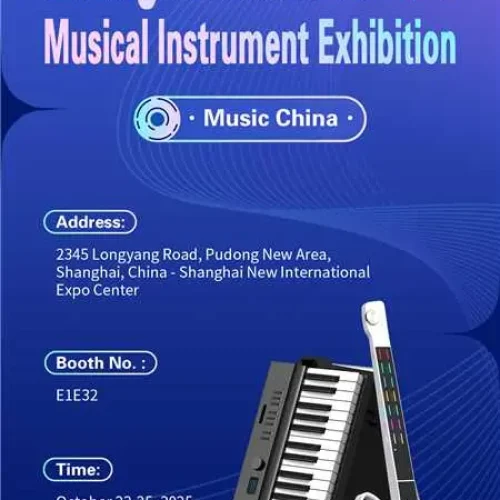

Visit Konix: Experience the difference precision engineering makes. [Optional: Include a call to action like “Contact us today” or “Explore our capabilities at www.konix.com“]